In mid-1960’s, a Canadian businessman named Bob Gavin asked his patent attorney Bob Beech of Seattle, “What’s new?” Mr. Beech lifted his long, hairy eyebrows, gave Mr. Gavin the look and proceeded to tell him about another client, Jim Cox, who was having a hard time paying his legal fees on a number of outstanding patents, all pertaining to nutrition science and/or pollution control. The result of this inquiry led to Mr. Gavin generously paying off Jim’s legal fees and asking Jim to come work for him in Vancouver, B.C. with one of U.K.’s largest rice importers. This worked out nice for Jim and Jeanne as they were already into rice, not only feeding their growing family with it, but understanding the enormous applications and opportunities rice presented in the global market.

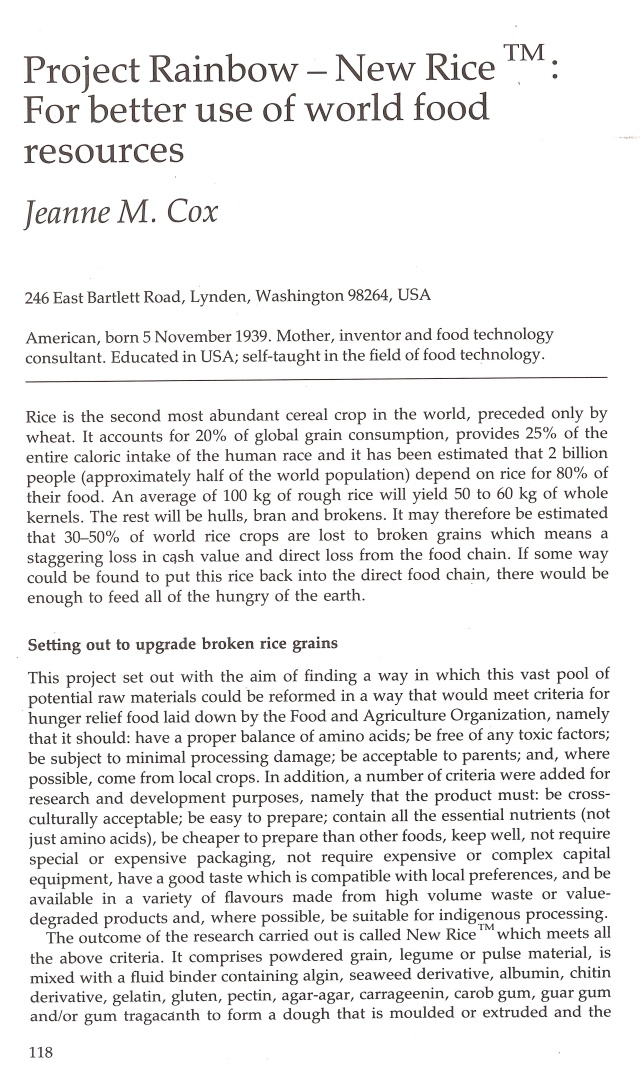

Back then, rice was the second largest abundant cereal crop in the world, trailing slightly behind wheat. Half of the world’s population depended on rice for 80% of their food. Some 30-40% of the rice produced globally consisted of broken grains which were discarded or milled into flour, resulting in staggering loss in cash value and direct loss for the food chain.

Jim and Jeanne’s idea was to utilitize the wasted broken rice grains and produce a nutrition-enhanced instant rice product to fight world hunger. The first criteria for feeding the people was to create a nutritious food that could be identified by the indigenous people. Second, the food should be easy to prepare, even in the crudest method on a dung burner, in less than five minutes, all the while maintaining it’s integrity as a recognized food. The rice should be fortified with protien, which was easy, and also vitamins A and D, which were not so easy to formulate to stand up to high tempertures during the cooking process. The importance of vitamin A is crucial in nutritional feeding as the lack of it can lead to blindness. Jim discovered sodium alginate and calcium chloride, together with vitamin E encapsulated the starch in the broken rice grain, so when it came off the heat, it would still be intact. Sounds simple, but for this family-based food invention, it took years to figure out.

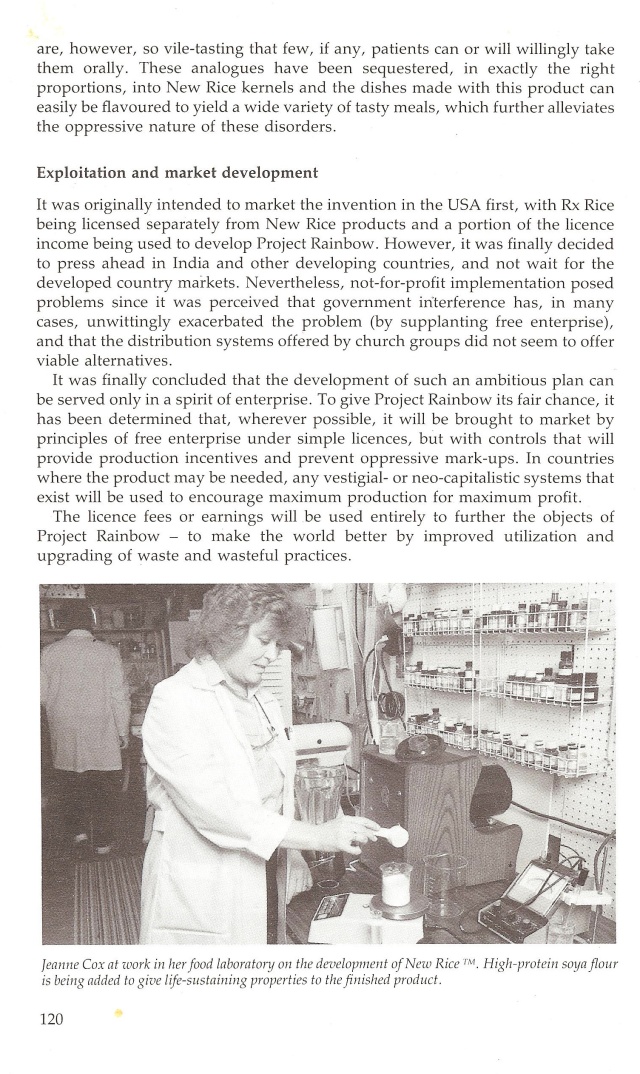

“After my parents put us kids to bed, they’d be up late into the night experimenting in the kitchen. Dad would take notes while Mom ground rice flour in the KitchenAid mixer I still have today. Dad would give instructions as to what ingredients to add to each small batch. Mom would roll the dough out as fine as possible and actually handcut rice kernels with a knife. Batch after batch failed in some way, thus making their time together adventurous I suppose. The next morning I always inquired as to what happened.” – Kelly Cox

Mr. Gavin died suddenly in an automobile accident. Devistated, Jim and Jeanne moved their family back to the United States in 1973 and bought property on Wiser Lake, outside Lynden, Washington, a few miles south of the Canadian border. There the existing chicken coop became Jim’s new laboratory where long-time devoted family-friend John Paprocki dutifully assisted. John’s unmatched loyalty to Jim and Jeanne, in all aspects of their professional and family life, spanned more than 20 years. He was the closest non-family member and an unsong hero throughout this time. “John Paprocki had a natural mind for math and science, coupled with his warm heart, he was a constant in our camp.” – Kelly Cox

Another form of support came in the way of encouragement, friendship and generous financial contributions from a gentleman named John Soutter. “John Soutter recognized the potential in my parent’s work and wanted to be a part of doing something good for humanity. All of our work was towards a much bigger picture than just ourselves.” – Kelly Cox

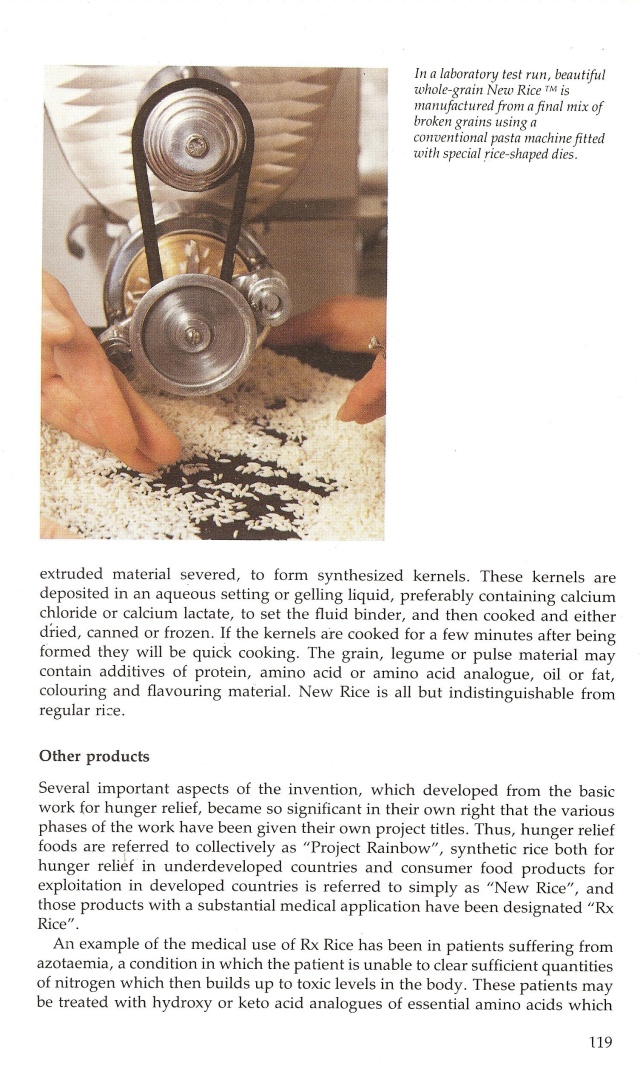

With the foundation for Ultra Rice’s formula developed, Jim invested in a La Parmigiana commercial pasta machine with an orzo-shaped dye, which under the right pressure, simulated a whole grain of rice. A large grinder was purchased used from a bread company to make rice flour. Samples of Ultra Rice were easier to make, but the batches produced only a few pounds of finished product. In time, it became necessary to scale up and produce Ultra Rice on a commercial level so it could be tested in the marketplace.

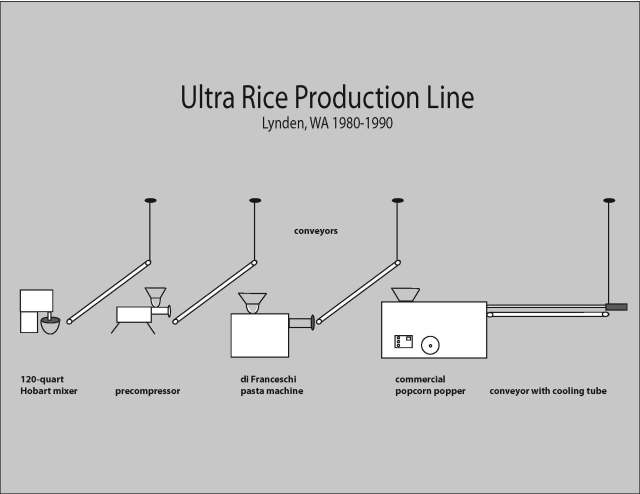

“In 1978, when I turned eighteen, I cut my long hair, started carrying a briefcase and went to work for my father. My new job was to build a mini-scale commercial production facility for Ultra Rice out of the plant we had been using to make fish bait. Dad insisted we never throw money at problems, so we built much of our own equipment from used parts that we already had. Everything we did was based on Ultra Rice’s formula, which was continuously being altered to fit the new production facility. I’d wake up to new handwritten instructions Dad wrote out the night before having discerned that day’s work. We ran hundreds of formulations with many failures those first few years – big messes to clean up, thousands of pounds of rice thrown away.

Eventually, the plant tuned-in with a 120-quart Hobart mixer to blend the rice flour with the other ingredients, a precompressor we built from a Toyota transmission and a meat grinder that pressed the dough flat onto a conveyor belt which fed into a larger di Franceschi pasta machine for cutting into orzo-shaped rice grains. A second conveyor fed the rice into commercial popcorn popper which heated the rice grain to the point of just splitting and boiling the inside starch, making it an istant rice. Afterwards, a third conveyor completely constructed from used parts with a leaf blower blowing cool air through a 4-inch wide PVC pipe vented to quickly cooled the rice to protect the added vitamins A and D. The rice was then steamed by an old steam generator we pushed to the limit by removing the safety valve, however we did take precaution and place the steamer outside the plant in case it blew up, nothing or no one would get hurt. Finally the rice was dried in a large dryer and safely bagged before “Herkermer” the plant cat found it.” – Kelly Cox